The Saxlund coarse material separator protects your system by removing any unwanted objects

from the infeed material. By separating out the contaminants that are too large for further pro-

cessing, there is less damage done to your plant machinery and a higher prevention of failures

further downstream.

A plant shutdown caused by jammed material can quickly become expensive, especially if the

foreign objects damage the system components. The Saxlund coarse material separator en-

sures only suitable material is passed through your system processes.

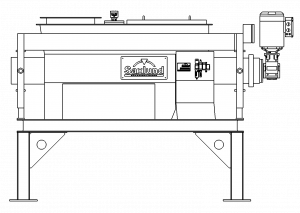

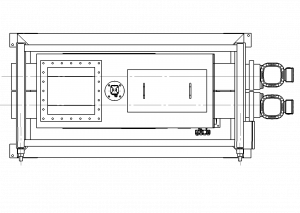

Working principle:

The foreign bodies are conveyed laterally by the grooved roller against a pendulum flap. The flap is opened

by the pressure of the impurities and separates them through the ejection chute. Material that cannot be con-

veyed by the grooved roller passes through the gap. The flat roller is moved linearly together with the bea-

ring, the displacement is detected and the system is switched off. The foreign body is removed by hand and

the separator is restarted.

Advantages of the Saxlund foreign object separator:

– Solid construction – solid profile steel

– Reliable in continuous operation

– Dynamically balanced rollers for smoother running and less noise

– Low maintenance costs, hardened rollers for longer life

– Low energy consumption

| Technical Data | WSA-1400 |

|---|---|

| Medium | Sludge with foreign objects TS 15 - 50 % Density 850 - 1100 kg/m³ |

| Throughput Capacity | Up to 25 m³/h |

| Roller | Wear-resistant design according to the medium |

| Roller Design | Flat and grooved rollers |

| Rotary Speed | n = 300 min -1 |

| Power | 2 x 9,5 kW |

| Gap Between Rollers | 5 to 25 mm |

| Degree of Seperation | Depends on gap between rollers |

| Weight | ~ 4500 kg |

| Foreign Object Outlet Opening | 200 x 300 mm |